A Comprehensive Guide to Concrete Admixtures: Types, Selection, and Applications

Concrete admixtures play a pivotal role in modern construction by enhancing concrete properties. These additives improve durability, strength, workability, and resistance to environmental factors. This guide explores the most common admixtures, their classifications, supplier sourcing methods, and typical applications to help professionals make informed choices.

Section 1: Top 5 Commonly Used Concrete Admixtures

Concrete admixtures are additives mixed into concrete to boost performance. Here are the five most widely used types:

1. Water Reducers

Also called plasticizers or superplasticizers, these admixtures cut water usage in mixes. They enhance flowability without sacrificing strength, making concrete easier to place and finish. Water reducers account for 30–40% of total admixture usage, leading their popularity in high-strength and pumped concrete projects.

2. Accelerators

Accelerators speed up concrete setting and strength development. Contractors use them in cold weather or projects needing rapid progress, such as infrastructure repairs. Common types include calcium chloride and non-chloride compounds, comprising 10–20% of admixture use.

3. Retarders

These slow down setting times, ideal for hot weather or large pours. Retarders like sugar-based agents or lignosulfonates prevent premature hardening, giving more time for placement. They make up 10–20% of admixtures, crucial for complex designs or extended work periods.

4. Air-Entraining Agents

These create tiny air bubbles in concrete to resist freeze-thaw cycles. The bubbles relieve pressure from freezing water, reducing cracks. Used in cold climates, they represent 5–10% of admixtures, enhancing durability in structures like bridges and parking lots.

5. Corrosion Inhibitors

Designed to protect rebar, these admixtures form a protective layer against rust. They are vital in coastal or industrial environments, where chlorides or chemicals threaten steel. Corrosion inhibitors typically account for less than 5% of usage but are critical for long-term structural safety.

Section 2: Classifications of Key Concrete Admixtures

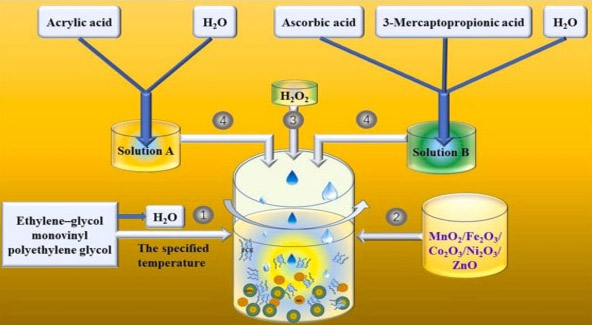

Types of Superplasticizers

Superplasticizers improve workability while reducing water content. Common types include:

– **Polycarboxylate Ether (PCE)**: Popular for high water reduction and flowability, available in liquid or powder forms.

– **Sulfonated Melamine Formaldehyde (SMF)**: Used in precast concrete for moderate water reduction.

– **Sulfonated Naphthalene Formaldehyde (SNF)**: Long-standing choice for slump improvement and strength retention.

Accelerator Varieties

Accelerators differ in composition and application:

– **Calcium Chloride**: Inexpensive but risky for rebar if overused.

– **Non-Chloride Options**: Safer for reinforced structures, using calcium nitrate or triethanolamine.

– **Silica Fume**: A pozzolanic by-product speeding up hydration and strength gain.

Retarder Categories

Retarders function through different mechanisms:

– **Sugar-Based**: Sucrose or glucose delay hydration by altering cement reactions.

– **Lignosulfonates**: Derived from wood pulp, they bind to cement particles to slow setting.

– **Organic Acids**: Citric or tartaric acid inhibit calcium carbonate formation, extending work time.

Air-Entraining Agent Types

These agents vary in composition and effectiveness:

– **Surfactant-Based**: Synthetic chemicals for stable, uniform air bubbles.

– **Vinsol Resin-Based**: Derived from pine wood, forming protective films around air voids.

– **Emulsion-Based**: Oils or fatty acids preventing bubble coalescence in mixes.

Corrosion Inhibitor Classes

Inhibitors protect steel through different mechanisms:

– **Anodic**: Form protective films on steel surfaces to block corrosion.

– **Cathodic**: Reduce electrochemical reactions using nitrites or phosphates.

– **Vapor-Phase**: Volatile compounds creating protective atmospheres around rebar.

Section 3: How to Find Reliable Concrete Admixture Suppliers

Finding the right supplier ensures product quality and project success. Consider these methods:

1. Online Searches

Use Google with keywords like “concrete admixture suppliers” to discover global or local vendors. Visit company websites to check product ranges, certifications, and contact details.

2. Industry Directories

Platforms like Thomasnet or Construction Directory list verified suppliers. Filter results by location, product type, or capacity to find suitable partners.

3. Trade Shows and Exhibitions

Attend construction events to meet suppliers face-to-face. These venues showcase new products and allow direct technical discussions.

4. Online Marketplaces

Websites like Alibaba or specialized building material platforms offer supplier comparisons. Read reviews and request samples before finalizing orders.

5. Sourcing Agents

Hire experienced agents like Goodcan Trading to vet suppliers. They handle logistics, quality checks, and negotiations, saving time and reducing risks.

Section 4: Typical Applications of Concrete Admixtures

1. Water Reducers in Use

– **High-Strength Concrete**: Lower water-cement ratios for superior compressive strength.

– **Pumped Concrete**: Improved flowability for long-distance or high-rise placements.

– **Harsh Environments**: Reduced permeability to resist moisture and chemical damage.

2. Accelerators in Projects

– **High-Rise Buildings**: Faster setting to meet tight construction schedules.

– **Cold Weather Sites**: Enable concrete curing in low temperatures to avoid delays.

– **Infrastructure Repairs**: Rapid strength gain for quick reopenings of roads or bridges.

3. Retarders in Practice

– **Large-Scale Projects**: Extended work time for complex pours in stadiums or industrial facilities.

– **Hot Climates**: Counteract rapid hydration, preventing early drying and cracks.

– **Decorative Concrete**: More time for detailed finishing in intricate architectural designs.

4. Air-Entraining Agents in Structures

– **Cold Regions**: Protect against freeze-thaw damage in residential and commercial buildings.

– **Bridges/Highways**: Durability against deicing salts and harsh weather conditions.

– **Parking Garages**: Resistance to moisture and temperature fluctuations.

5. Corrosion Inhibitors in Use Cases

– **Coastal Structures**: Shield rebar from saltwater corrosion in piers and sea walls.

– **Industrial Facilities**: Protection against chemical exposure in factories or wastewater plants.

– **Infrastructure**: Longevity for bridges and tunnels exposed to deicing agents or pollutants.

Conclusion

Concrete admixtures are essential for modern construction, offering solutions for strength, durability, and environmental challenges. Choosing the right type depends on project needs, climate, and material compatibility. By following these guidelines and sourcing from reliable suppliers, engineers and contractors can enhance concrete performance and ensure long-lasting structures. Always consult experts or manufacturer guidelines to tailor admixture use to specific applications.

Our Professional Technical Team Is Available 24/7 To Address Any Issues You May Encounter While Using Our Products. We Look Forward To Your Cooperation!